M1

M1 is the follow-up design to the Torch T2 helmet based on customer requests, market research and feedback from local retailers. The challenge was to fit a light powerful enough to light a path, yet small and light enough to integrate into a helmet along with added ventilation and a full visor.

While the T1 was designed for urban riders, the M1 was designed for mountain, trail and suburban riders who need to light their path ahead. Putting the light into the helmet makes it easier to see over obstacles, around corners and check for cross traffic compared to handlebar mounted lights.

The original direction was to create a much more athletic and angular design aesthetic for a complete line of mountainbike and road helmets to contrast the classic urban style of the original T1 helmet. After making the decision to grow the line to only one urban, mtb, and road helmet, it made better sense to have them share the same subtle style of the T1/T2.

Using the CAD from the T2 I was able to have the general shape milled out of polyurethane foam so that I could position the air vents on the physical form manually rather than in 3D CAD. This allowed me to skip the clay model stage, yet ensure that the vent placement and alignment looked nice in a physical sense.

The coating and cleanup of the foam went quickly using my automotive restoration/paint experience.

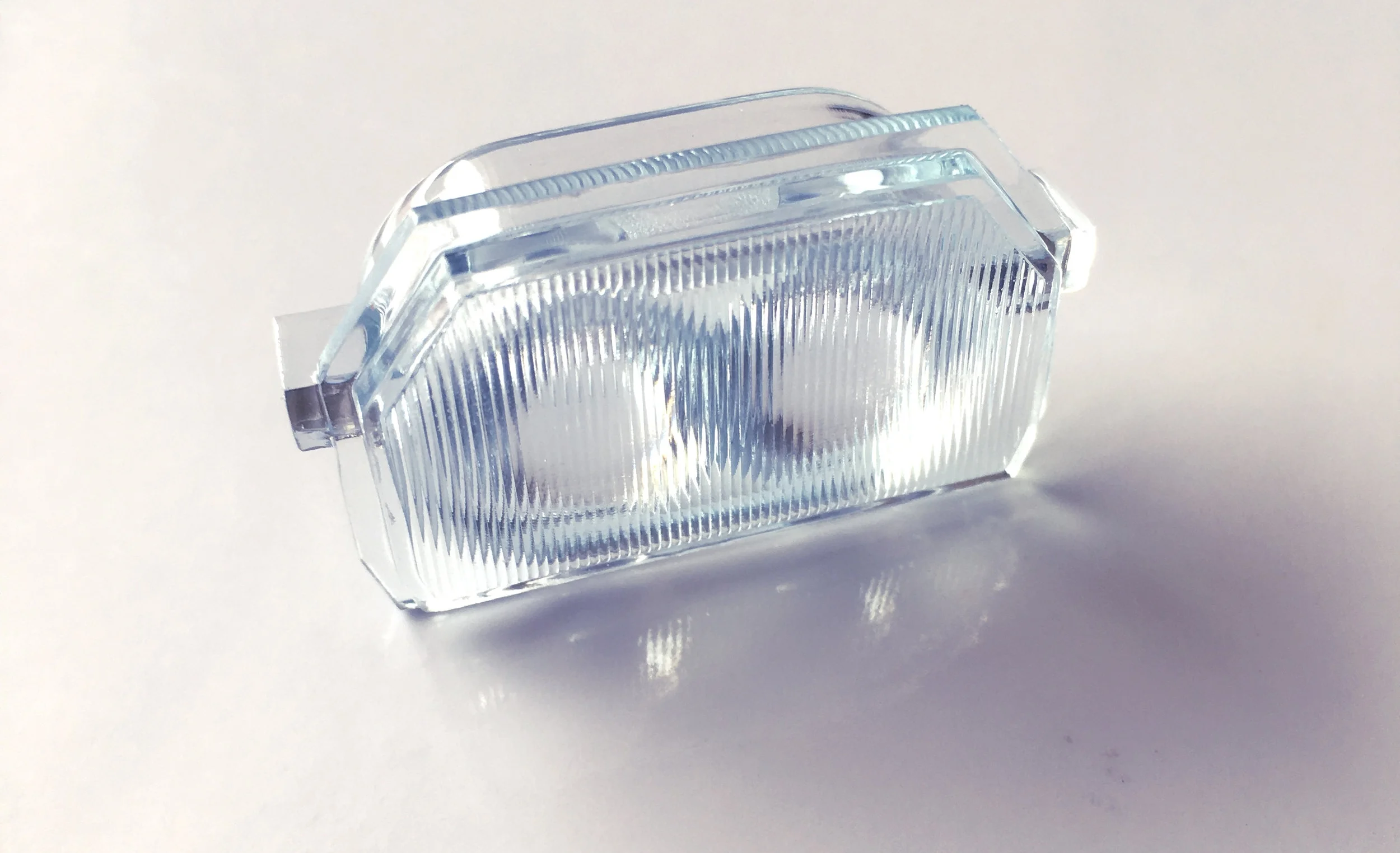

Other than reducing the size and weight of the light module for the helmet, creating a unique, dual LED lens that would create a 30 degree wide beam with a 500 lumen output and side emitting nodes was the biggest challenge in designing the M1. A typical bike light of this power uses a 10 degree wide beam which requires less power and focus.

While many high-powered bike lights choose to sandwich an aluminum heat-sink between plastic housings to save cost, I decided that making the entire housing using metal injection molding would make the heat sink perform better and save on tooling costs. It would also create a superior product in the end.

Aside from all of the engineering challenges of this product, the challenge of integrating a linear attachment into a spherical product became difficult aesthetically. While I started with more athletic looking light housing designs, in the end the interior components and helmet requirements were the key drivers for the light housing package and I'm very happy with the end results.